Pear Cable Redux: How to Combat Scam with Science

A Case Study in Applying an Audioholics A/V Education to Identify Marketing Drivel

In our first article, we looked at the saga of Pear Cables and the challenge by the James Randi Education Foundation to prove that some seriously overpriced Pear Anjou speaker cables made any difference in controlled testing conditions compared to common Monster Cable. Much smack talk ensued from both sides of the challenge, but ultimately, Head Pear Adam Blake turned tail and ran.

In this follow-up piece, we will look at Pear Cable as a case study in evaluating exaggerated marketing claims about the audio performance improvements attributed to cables. We will use known science, established engineering principles, and the educated opinions of well known audio engineering practitioners to look for contradictory statements, mistakes and misuse of engineering knowledge, and exaggeration of the audible significance to certain aspects of audio performance.

Pear Cable was chosen for this case study not to specifically single the company out, but because they are currently a high profile example of just what Audioholics has spoken out against when dealing with unfounded advertising claims based on sciency sounding jargon without any real root in science. The same analysis can be applied to any other cable manufacturer who uses exaggerated or fictitious claims to sell product. Pick a favorite overpriced audio cable manufacturer, strip the words Pear Cable out of the article, and insert the other manufacturer’s name. Yes, the particulars will vary, but the over-hyped claims and misuse of scientific principles always leads to the same end.

The controversy surrounding the claim to audible improvements due to cabling are widely known and the effects of wire are generally reported as insignificant by many sources outside of subjectivist audiophile circles. Numerous engineering experts in various fields of electrical, audio, and loudspeaker engineering have also stated this opinion. Such experts include Dr. Howard Johnson of Signal Consulting Inc., John Dunlavy most recently of Dunlay Audio Labs, and Roger Russell formerly Director of Acoustic Research for McIntosh Laboratory. Each of these gentlemen has spoken out against exaggerated claims of cable effects on audio reproduction in various venues; Mr. Russell, the man behind the McIntosh Loudspeaker Division from its inception in 1967 until 1992, goes as far as actively criticize exotic cable performance claims on the web site he maintains.

Several important questions must be answered when evaluating marketing claims for scientific validity about the effects of cable design on audio performance:

- What established scientific knowledge supports the purported design issues?

- How is established science applied to provide an engineering solution to these issues?

- Do these issues produce significant audible effects that warrant design effort and cost?

We will take an extensive look into just these questions.

I will start by referring readers to Audioholics’ extensive library of documentation debunking nonsense cable design based on published research, mathematical calculations, and well known engineering principles that are supported with opinions from academics, practitioners, and other cable manufacturers who do not push over priced, high profit margin exotic cables. Several overview articles are linked here and many others are linked with specific topics:

- Audioholics: Top Ten Signs an Audio Cable Vendor is selling you Snake Oil

- Audioholics: The Truth About Interconnects and Cables

- Audioholics: Audio Cables Science or Religion?

- Audioholics: Calculating Cable Inductance of Zip Cord

- Audioholics: Interview with Dr Howard Johnson about Skin Effect

We will find that every topic Pear claims is important to cable design has been debunked as nonexistent, inaudible, or insignificant at audio frequencies. Coupled with the fact that exotic cable designs are not used by the professional broadcast and recording studios that produce the recordings in the first place, this non-issue of cables is further diminished in significance.

Measurements: A Wealth of Scientific Information, and Expert Opinion

In the email correspondence reproduced on Gizmodo, Mr. Blake took umbrage at James Randi for calling Pear’s cable science junk. In between bouts of disparaging Mr. Randi for a high school education, Mr. Blake stated that Pear Cable’s performance claims are backed by all sorts of measurements, a wealth of scientific information, and expert opinion.

What measurements, scientific information, and expert opinion back Pear Cables, one might ask?

Let’s examine this claim of substantiated proof that cables make an audible improvement to sound quality based on the cited references.

Measurements: a single frequency response plot of some unnamed Pear cable on the web site.

Scientific information: an unsourced statement about RFI effects on speaker cables from the American Radio Relay League, an amateur radio association:

Although this high frequency noise cannot be heard directly, it has been well documented by professional organizations such as the American Radio Relay League that RFI can still be a problem in audio applications.

Pear Cable: Anjou Speaker Cable

Expert opinion: testimonial by some guy named Richard from the Bay Area Audiophile Society supposedly based on blind testing:

The Comice Silver Interconnects kick some audio butt.

- Richard, Some Guy

The ARRL is not a professional organization, it is an amateurs or ham radio organization. While the ARRL does provide an extensive array of educational and general technical information about radio broadcasting for its members, as an amateur organization, it is not a suitable to support professional opinions or conclusions as an engineering reference.

Furthermore, without any particular source cited for the

statement there is no way to evaluate the applicability of what the ARRL might

have said regarding RFI and audio to this particular audio application. A

group like the ARRL is much more likely to be discussing the problems of

parking several thousand watts of RF broadcast amplification next to the

neighbor's consumer audio gear than to be discussing the need for very expensive

audio cables to solve the problem of random stray radio interference on

someone's hi-fi.

As to the other two components of proof that Pear Cables is addressing

legitimate cable engineering issues, well...

The testing conditions of the provided measurement are poorly documented at

best and really are completely out of context making them worthless.

Finally there is some guy named Richard who really likes his stereo so much he joined the Bay Area Audiophile Society, a group of people who also really like their stereos. I think the scientific validity of this one speaks for itself.

A Summary from the One Legitimate Reference

There was one reference provided in Pear’s response to the challenge that seems a more reputable source for engineering information, an article on Audio DesignLine, Loudspeakers: Effects of amplifiers and cables, a reprint of excerpts from the book Loudspeakers for Music Recording and Reproduction, authored by Philip Newell, acoustics consultant and Keith Holland Ph.D., Institute of Sound and Vibration Research, University of Southampton. The article, in six parts, concerns the effects of speaker cables on both audio recording and reproduction. After some introductory information on amplifiers in the earlier sections, part 4 and part 5 gets into the question at hand.

On the surface, this article does seem to support Mr. Blake’s claims about audio cables; that is until one actually reads it. According to the article, cables can sound different but not exactly for the reasons typically espoused by cable manufacturers to support buying overpriced cables; a view head Audioholic Gene DellaSala shares and espouses regularly on this site.

The general electrical behavior of speaker cables and amplifier/cable/loudspeaker circuit can be summarized:

- Low impedance is important to speaker cable

- Impedance is dominated by resistance at low frequencies

- Impedance is dominated by inductance at higher frequencies

- Capacitive reactance is insignificant compared overall circuit impedance and will only affect signals that are well over the +100 kHz range

The article discusses test results obtained from various combinations of amplifier, loudspeaker, and cable types over different cable lengths. I will summarize (note the trend in cable length):

- Cable properties can be shown to affect the impedance interaction of certain amplifier/cable/loudspeaker circuits with 6 meter (19.5 ft) cable lengths

- Esoteric geometries (Litz, bi-metal plating, etc.) only seem to show any significant reduction of skin effect for long cables, over 10 meters (32.8 ft)

- EMI interference is negligible for various 5 meter (16.4 ft) cable designs but become pronounced and varied at 50 meters (164.0 ft)

- Various amplifier class topologies showed different susceptibility to interference on various 28 meter (91.9 ft) cable designs

- High sensitivity speaker drivers are more susceptible to interference

- Different cable construction will behave differently in impedance and noise rejection

Summarizing what these fellows are saying about cable affects on audio performance:

- Unstable esoteric audiophile amplifiers that are overly sensitive to cable properties are the real culprits

- Any effects from cable properties are so system specific that there is no general solution to improve sound quality with cables

- There will be no difference in properly designed cables below 2 meters (6.7 ft) length irregardless of amplifier/loudspeaker combination

- Using the shortest, lowest impedance cables possible is the only universal way to minimize effects of cable electrical properties

Any perceived difference in performance due to cables has more to do with esoteric audiophile amplifiers used in home audio, amplifiers that do not have robust, stable designs. The types of overly sensitive amplifiers, beloved by audiophiles, can be knocked out of kilter by cable properties that are not complimentary to their idiosyncrasies when coupled to a particular loudspeaker. As the authors clearly state:

An idiosyncratic, 8 watts per channel valve amplifier has rarely found a home in a professional recording studio, and especially not if it cost 5000 euros or more.

It is therefore worth re-emphasizing that the innumerable stories about either input or output cables magically changing the sound of domestic equipment (whilst a giant and highly respected organization such as the BBC has 'no policy' on esoteric cables) are more a testament to the sensitivity of much domestic equipment to minor changes in termination than to the general importance of esoteric cable design or materials of construction. However, that is not to say that cables are cables, and that any cable will suffice for connecting a loudspeaker as long as it manages not to catch fire at full volume.

Loudspeakers: Effects of amplifiers and cables

If one owns an amplifier that gets squirrelly with certain cables or is even bothered by cables at all, it is best to consider a better, not necessarily more expensive, amplifier that is not so touchy because using cables in this way does not solve the fundamental problem that still exists with the amplifier. It is this engineer’s opinion that any properly designed amplifier, one with low output impedance, proper usage of negative feedback, and a good power supply, is the best way to solve cable problems, and it would seem to be the solution favored by the authors as well.

One great problem about generalising about many, or most, of the effects of the performance of loudspeaker cables (once the basic properties of resistance and inductance have been adequately specified) is that their effects can be so system-specific. In other words, what occurs with one combination of amplifier, loudspeaker and location may have very little in common with what occurs with a different combination.

Loudspeakers: Effects of amplifiers and cables

Ideally, cables should have no effect on audio quality whatsoever; they should be a transparent transmission medium. Any movement towards this ideal due to cable interaction with other system components only reduces detrimental effects to sound quality, a subtle but important distinction from the idea of improvement that is bandied about. Because of the massive number of possible permutations in available amplifier/loudspeaker combinations, it is essentially a random phenomenon. This means that there is no single cable design that could work with every possible combination to minimize deleterious effects to sound quality through complimentary properties. It far more likely that a particular cable design will not have any effect on audio quality at all and, although a remote possibility either way, at least as likely that the cable properties are not complimentary to a particular system as it is likely that they are complimentary. This is most certainly not what high priced cable manufacturers are claiming when they try to sell their wares.

This leads back to the Audioholics stance that any properly designed cable is as good as any other. The basis of the statement is supported in probability.

Best of all, following publication of Mr. Blake’s cited reference on Audio DesignLine, Managing Editor Rich Pell, BS Electrical Engineering, had the following to say concerning the aforementioned article on audio cable differences:

So what's the most reasonable presumption concerning audio cables? Technically, there's little or no reason to believe they should sound different under most normal circumstances, and there's every reason to be skeptical about claims to the contrary. Also, trying to prove a negative - in this case that audio cables don't sound different - is difficult, to say the least.

In court, it isn't up to the defendant to prove him/herself not guilty - it's up to the prosecutor to prove that they are. Likewise, the onus is on those who claim that audible differences commonly exist among cables to prove their case - that cables are "guilty" of sonic differences.

Have they? Not as far as this juror is concerned, which leaves only one possible verdict: Not guilty.

Case dismissed.

Rich Pell: Are audio cables guilty of sonic differences?

Pear Cable Designs Revealed, Well, Sort Of

As something of an engineer myself, I decided to visit Pear’s site and peer review the technical literature that they publish:

- Pear Cable: Anjou Speaker Cable

- ANJOU analog interconnect Electrical Properties

- A Technical Introduction to Audio Cables by Pear Cable

- Cable Design, Audio Cable Design of Pear Cable Inc.

Interestingly, Pear’s documents do not offer any scientific proof that their cables can achieve any significant sonic improvement to justify the cost. There is a lot of general scientific explanation about inductance, capacitance, and impedance, as well as quasi-scientific marketing drivel claiming significance that often defends itself with we can’t tell you more because it’s a secret:

While most of the design is proprietary, we can tell you that each cable (not pair) has 25 separate parts not including the connectors!

While it is unfortunate that more details about ANJOU cable geometry and construction cannot be disclosed for confidentiality reasons, we hope that some light has been shed on the rationale behind the overall design philosophies.

The referenced documents contain a wealth of unsupported statements, various claims about what constitutes good and bad cable design, and numerous unqualified statements that Pear Cables are better than some unnamed competition.

The purity of the sound transferred by Pear Cables is unrivaled.

The result is sonic beauty without compare.

Pear Cable: Anjou Speaker Cable

Oh the hyperbole. I would have again thought this as an aspect of the music, not of cables, my mistake.

At no point do the Pear documents provide any test data, any analytical proof with supporting calculations, or reference any published scientific literature that supports the audible significance of any claims made by Pear.

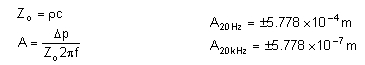

This is not to say that Pear Cables do not offer a sonic change. We now turn back to the anonymous frequency response plot that compares two unnamed cables, one a Pear, and the other some competitor.

response plot that compares two unnamed cables, one a Pear, and the other some competitor.

It is clear from the plot that neither cable can make a 20 kHz bandwidth with a flat frequency response. The Pear shows roll off somewhere between 8 kHz and 9 kHz, and while the other cable is indeed worse, neither is very good. Nevertheless, Pear applies bold hatching to highlight the difference in area under the curves to emphasize the superior Pear design.

Yes! It really does not matter what equipment you have. Because Pear Cables are designed to be sonically neutral, they will work well with any brand of equipment. Matching cables with certain brands of equipment is only important when buying cables that have a known tendency to “color” the sound. Pear Cable does not design any of its products to produce “coloration”.

Pear FAQ 7: Will the cables sound good with my specific brand of equipment?

While there is nothing wrong with listening to music through what is effectively a filter, it is our firm belief that it is difficult to compete with the sonic neutrality that Pear Cables strive to achieve.

Sonic neutrality is a flat frequency response from 20 Hz to 20 kHz; any deviation from flat response is quite simply coloration. The measurements are presented as voltage loss, but this is a technical slight of hand. Not presenting the plot in the more customary decibel is perhaps just enough to throw off the non technical buyer from the fact that expensive Pear Cables do not pass signal over the full audio band and is clearly is acting as a low pass filter for high frequencies. Based on the shape of the curve, I would conjecture that the cable is appealing to Audiophiles with solid state amplifiers who crave the rolled off sound of a valve amplifier, which is, of course, coloration.

As to the competitor, we have no idea who this is, for all we know, it may just be a straightened coat hanger jammed into the speaker terminals. While the competitor clearly performs worse than the unnamed Pear Cable does, the Pear still is not good. This is simply a tactic to deflect attention away from the shortcomings in the Pear cable: see, look, these guys are worse.

If Pear has spent as much time and money engineering the impedance of the Anjou speaker cables to provide a sonically neutral response as they claim, the cable response should be flat and only produce a uniform loss resulting in a slight decrease in overall volume.

What happens when the resistance gets too high? First, there is power lost in the wire and the speaker will not play as loud. More important, as the resistance in series with the speaker increases, it makes the amplifier look more like a current source. This means the speaker frequency response will tend to follow the rise and fall of its impedance curve. The greater the impedance variation, the more noticeable the response changes will be. If the speaker has constant impedance versus frequency, the only change will be reduced output.

Contradictions Abound

The cable companies that utilize faulty scientific conclusions can be spotted by the factual errors presented in their design philosophy, or misuse of otherwise sound engineering principles.

While Pear provides no scientific support as to significance of any claims to audible improvement due to cables, they do provide many internal contradictions that when cross-referenced between various documents. The design documents themselves haphazardly jump between talking about interconnects, then speaker cables, and then interconnects.

While reading I noticed certain statements that are much more interesting when juxtaposed directly rather than when obfuscated by separation over five intervening pages:

One of the most common questions asked by consumers faced with purchasing cables for their audio or home theater system is, “What is so important about cables anyway?” They can cost as much or more than some of the hardware in the system and to many it is difficult to understand why wire isn’t just wire.

Opening paragraph from:

A Technical Introduction to Audio Cables by Pear Cable

It is fairly safe to say that no matter what cable you use, the modifications to the sound will be small.

Penultimate paragraph from:

A Technical Introduction to Audio Cables by Pear Cable

Pear believes it is reasonable to spend more on cables than other hardware in the system for what will admittedly be of small benefit.

Next up is capacitance, which Pear at first says is not important for speaker cables, and then suggests otherwise:

Loudspeaker cables, on the other hand, are far more sensitive to inductance rather than capacitance due to the relatively high current nature of the signal.

Pear Cable: Anjou Speaker Cable

As stated previously, interconnect cables carry a very small amount of current. Relative to the current the voltage is large. Because of that fact, capacitance is important, but inductance is relatively unimportant.

The signal in loudspeaker cables is essentially the opposite of the signal in interconnects. Both cables have the same information, but in loudspeaker cables, the voltage is small and the current is large, relatively speaking. Because of the high current, both resistance and inductance are important in loudspeaker cables.

A Technical Introduction to Audio Cables by Pear Cable

This is one of the lowest, if not the lowest capacitance speaker cables that is able to achieve such low inductance. While some cables can achieve lower inductance, these cables typically suffer from capacitance 50% to 10 times higher. Cables that achieve lower capacitance cannot match the low inductance of the ANJOU Speaker Cable. The ultra low reactance allows for extremely accurate energy transfer.

Pear Cable: Anjou Speaker Cable

This is an interesting contradiction of both the Pear design papers as well as the cited Audio DesignLine source. The product description goes on about how the various other speaker cable geometries have higher capacitance than Pear, Pear Cables are designed for low capacitance, and that the speaker cables from other manufacturers just can’t match Pear.

Litz designs minimize skin effect, can offer low inductance, and braided litz designs have good rejection to Radio Frequency Interference (RFI). However, these cables can suffer from excessive capacitance, poor mechanical integrity, or poor RFI rejection for non-braided designs.

Pear Cable: Anjou Speaker Cable

Capacitance does not have a significant impact on speaker cable, so it does not matter that Pear is lower in a property that is not significant to the design and performance.

Then there is this foamed Teflon business:

There are many ways to create a Teflon/air insulation structure, and Foamed Teflon is one of the more common methods. Foamed Teflon is exactly what it sounds like; namely Teflon that has air bubbles injected into it. These air bubbles lower the overall dielectric constant of the insulation. It is commonly used because the mixture of air and Teflon can essentially be treated as one material, making fabrication processes simpler. One of the biggest problems with this insulation technique is that the overall dielectric constant is reduced, but the randomness of the bubbles creates a myriad of local anomalies. Large air bubbles on the surface of conductors are unpredictable and the associated dielectric constant variation causes a variety of transmission problems.

Foamed Teflon is never used in Pear Cable products and should not be used in any high fidelity audio cables.

Various, Cable Design, Pear Cable Inc.

Solid Teflon, foamed Teflon, Teflon air tubes, air, and cotton combine to minimize dielectric absorption while still providing superb mechanical integrity.

Pear Cable utilizes a dual layer primary insulation technique to avoid all of the above issues. An extremely fine layer of Teflon, 0.002” thick, is applied to conductors in a first step that protects the underlying copper. In a second step, foamed Teflon is applied on top of the first layer in order to provide superior dielectric properties and complete mechanical support. The final insulated conductor does not suffer from local anomalies in the electrical or mechanical properties, and minimizes conductor corrosion.

Various, Pear Cable: Anjou Speaker Cable

On one hand, Pear blathers on that foamed Teflon should never be used in any audio cable because it provides non-uniform dielectric properties due to the bubbles, but then states elsewhere that it is used. Ironically, the twisted geometry used in Pear interconnects will also be a source for the same issue of inconsistency in dielectric uniformity.

Pear Cable considers the proprietary cable geometry that it has developed for ANJOU interconnects, including “Perfect Twist” conductor arrangement, to be one of the most innovative and effective designs available.

“Perfect-Twist” noise rejecting geometry prevents the need for a shield around the two core conductors.

Pear Cable: Anjou Analog Interconnect

If local variations in the ratio of air to dielectric material are a problem for foamed Teflon, the same variability in the material surrounding the conductor will happen with twisted wire inside an insulating jacket. Pear states that they use an unshielded twisted pair interconnect cable design, which is hardly anything new as Perfect Twist is nothing but a variation on a standard low cost cable design that has been used for many years in telecommunications that Pear somehow has made expensive through proprietary techniques.

Twisted pair cabling is often used in data networks for short and medium length connections because of its relatively lower costs compared to fiber and coaxial cabling.

Wikipedia: Unshielded Twisted Pair Cable

Unshielded twisted pair cabling is used for its lower cost when compared to other cable types. Does this mean that if Pear used properly shield cable that they would have to charge even more than they presently do for their already very expensive cables?

Audible Significance and Engineering Minutia

In reading documents provided by Pear Cables about what is considered important design parameters for speaker cable, one will see an exercise in hyping minutia with no proof that any of it is significant or even humanly audible. The worries of Pear Cable designers:

- Litz geometry and Skin Effect

- Exotic metals and internal corrosion

- Cable dielectric absorption

- Triboelectric effect

- Internal mechanical vibration and resonance

- Internal cable damping

- Cable movement relative to connectors

- Extreme tolerances on conductor length

- Cable directionality

- Cable break in

First, we will define what constitutes the boundary between the audible and the inaudible:

Listeners can detect a change in loudness when the signal is altered by about 1 dB (a 12% change in amplitude).

Steven W. Smith, Ph.D., The Scientist and Engineer's Guide to Digital Signal Processing

Chapter 22 - Audio Processing / Human Hearing

A wide range of studies over the last century support 1dB as an average with the best result of 0.25 dB obtained only at inner ear resonance using wide band pink noise. Any sound outside of the commonly accepted 20 Hz to 20 kHz bounding frequency range of human hearing or any change in sound amplitude  < 1 dB is inaudible.

< 1 dB is inaudible.

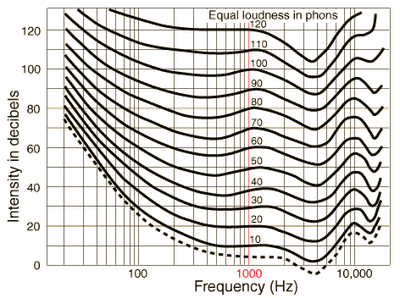

The other important fact is that the ear is relatively insensitive to low and high frequency sounds. The nonlinear response of the ear somewhat flattens out at high SPL, but the ear will simply be less sensitive to sound changes at frequency extremes.

Equal loudness contours after Fletcher and Munson

A 20KHz harmonic note (because that's what it is) represents the 5th harmonic of the highest fundamental frequency on a concert grand piano, 4156Hz. Frequencies in this lofty realm can be heard by a very young, small percentage of the world's population. Typically this frequency will be over 20dB down from the fundamental which means that relatively close proximity to the reproducing system in a very quiet acoustical environment is required to hear these frequencies by the select few who have the capability.

Audioholics: Speaker Cable Length Differences Do They Matter

As to phase and time delays:

A 5 microsecond delay has only been detected with any degree of certainty, under controlled laboratory conditions, within the approximate 3500Hz region where the ear is most sensitive. Again this detection must be in an extremely quiet environment, certainly below NC20, almost anechoic in fact.

Audioholics: Speaker Cable Length Differences Do They Matter

A 5 ms delay is the upper bound limit for human hearing in optimal laboratory conditions, and only within the frequency range where the ear is naturally most sensitive. Delays of up to 30-40 ms are combined by the ear in what is known as the Haas Effect, which is commonly used for sound reinforcement in PA systems, it allows stereo audio systems to recreate the illusion of a sound stage, and it is used as a basis for various matrix surround sound decoder schemes such as Dolby ProLogic.

So, what is the audible significance to the issues that Pear raises for audio cable design?

Pear boasts of a proprietary hybrid Coaxial/Litz geometry to prevent skin effect losses at audio frequencies, losses which are inaudible at mere fractions of a decibel.

At radio frequencies, Litz wire is often used to eliminate the skin effect. This occurs because of the tendency for RF to try to escape from the wire, so it concentrates on the outside (or skin) of the wire. The effect actually occurs as soon as the frequency is above DC, but becomes noticeable only at higher frequencies. Litz wire will not affect your hi-fi, unless you can hear signals above 100kHz or so (assuming of course that you can find music with harmonics that go that high, and a recording medium that will deliver them to you). Even then, the difference will be minimal.

Rod Elliott, Elliott Sound Products

Audioholics: The Truth About Interconnects and Cables

According to Dr. Howard Johnson, attenuation of signal transfer through any copper wire can be broken into five distinct regions:

Skin effect is not a significant consideration until well into the megahertz frequency range and audio falls well within the RC range with attenuations of 0.001 to 0.08 dB/meter at 20 kHz.

Attenuation curve for copper coax cables and a psb trace

Dr. Howard Johnson, High Speed Signal Propagation: Advanced Black Magic

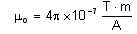

For solid copper wire, skin depth can be estimated as:

Frequency |

D |

|

60 Hz |

8.57 mm |

|

10 kHz |

0.66 mm |

|

100 kHz |

0.21 mm |

|

1 MHz |

66 µm |

|

10 MHz |

21 µm |

f = frequency (MHz)

At a frequency of 20 kHz (.02 MHz), the skin depth of a copper wire would be 0.47 mm, radially, meaning any wire of a 0.94 mm diameter or less would effectively have no skin effect.

Wikipedia: Skin depth for solid copper wire

Skin depth is larger than the radius of a 19 AWG (0.91 mm diameter) solid conductor and nearly that of an 18 AWG (1.02 mm diameter) solid conductor. Few, if any, audio cables are constructed from solid wire of this gauge or larger, meaning no significant skin effect. For frequencies lower than 20 kHz, skin depth increases and smaller wire increases the critical frequency before the wire cross section is not 100% effective. With skin depth increasing as frequency decreases, this effectively mitigates skin effect as an issue at audio frequencies.

Pear uses gold interconnect and OFC speaker cable conductors to eliminate internal surface corrosion, again related to skin effect.

The diffusion of oxygen, or other gases, through the insulation will be small, but the conductors will oxidize over time.

Most insulation jackets are effectively impermeable and any incidental oxidation results in copper oxide, an insulator.

Many cables today are advertised as using "oxygen-free copper”, copper which has been annealed in an oxygen-free atmosphere. OFC is popular in audio cables, and has begun to make inroads into the video cable market as well.

We all know, of course, that oxygen is bad for things made from copper. Copper oxidizes and turns green and flaky; in so doing, it loses its high conductivity and begins to fall apart. But the amount of oxygen present in conventionally annealed, non-OFC copper is so tiny that it simply isn't a factor in cable quality. We have cut into pieces of Belden coaxial cable twenty-five years old that have been used in radio transmission applications--and found them clean and bright, completely lacking any sign of oxidation. Modern coax is better still, with nitrogen-injected foam dielectrics that keep oxygen entirely away from the center conductor.

As it is with silver, there's nothing wrong with OFC; but electrically speaking, OFC wire is indistinguishable in audio and video applications from ordinary annealed copper wire.

Audioholics: Exotic Materials and Cable Construction

Internal corrosion will not occur with a conductor properly encased in a dielectric. Once again, this is nothing but minutia.

Oddly enough, it isn't the freedom of oxygen in copper wire that makes any difference. The process of removing oxygen also removes the impurity of iron and it's this impurity that can cause the resistance to be slightly higher. The difference in resistance between copper wire and oxygen free copper wire is too small to be significant for speaker wiring. It can be considered to be ordinary copper wire as far as the recommended lengths of copper wire in the table. Oxygen free copper wire can be more expensive than ordinary copper wire.

What is also ironic is that gold is actually a worse conductor than either copper or silver, but is used by Pear to prevent cable corrosion that does not occur anyways.

Pear obsesses about dielectric absorption; another inaudible non-issue that causes high frequency losses an order of magnitude below established thresholds of human hearing and does not produce any measurable distortion between different materials and cable designs.

Pear claims internal cable components will undergo significant mechanical movement from acoustic and electromagnetic forces: minutia. Other than citing an exotic design where the internal conductors are deliberately loose in the cable sheath, this is a non-issue for any standard cable design.

The ANJOU Speaker Cable has been meticulously designed to minimize physical movement within the cable. Movement of conductors relative to themselves or insulation material will cause energy to be either subtracted from or added to the audio signal. Vibration caused by sound waves must be dealt with in all cables. In addition, speaker cables can resonate from the electromagnetic force caused by the current within the cable itself. There are 3 important elements to consider when minimizing mechanical movement within a cable: ability to absorb or dampen mechanical energy, the strength to prevent motion, and the electromagnetic forces that will be will be created within a cable.

Pear Cable: Anjou Speaker Cable

The bit about strength to prevent motion is a factual error in applying mechanics of materials. Mechanical strength is defined by the ability to resist load without material failure by a number of mechanisms including yielding, fracture, or rupture. The mechanical stiffness of a material, or its converse rigidity, or compliance in audio circles, is the ability to resist deformation caused by loads. This is a distinction introduced in every introductory class on engineering materials.

Pear cites significant Triboelectric Effect based on the supposed internal motion, the common source of static electricity from friction, an everyday occurrence when one, say, walks across carpet in socks on a cold, dry day. Triboelectric effect only occurs with kinetic friction, where one surface moves relative to another surface, not from static friction where no movement occurs. The transfer of energy from kinetic friction occurs because the movement produces mechanical work, but if there is no motion, no work is performed.

Triboelectric effect can be a consideration in microphone wires where a performer’s movement with the cable may introduce localized bending stresses high enough to cause localized internal slip. The movements of a performer will be measured in meters, producing high flexural curvatures with cables wrapped around tight radiuses; such movement falls into the range of a large deformation geometric nonlinearity.

Any incidental movement of a speaker cable from acoustic vibration and electromagnetic fields will not be enough to overcome internal static friction between components in standard cable designs, staying well within the small deformation, geometrically linear range. Static friction, in addition to any adhesion between the conductor and insulation, will generate enough force resistance to prevent movement: no movement, no work, and no triboelectric effect. So, unless one is running around carrying their speakers while listening to them, this is not a problem for speaker wire.

Pear then claims mechanical resonance at audio frequencies inside speaker cable. I would love to see the modal analysis and dynamic time history results, as well as the mathematical model, input, and assumptions that went into this claim, assuming there is such an analysis.

The significance of mechanical resonance in audio cables can be dismissed with some simple common sense. Under conditions of resonance, energy that is input into a system by a frequency that is at or very near a natural mode or frequency of vibration will cause a disproportionate, unbounded increase in the amplitude of the movement. Considering the harmonic nature of music, if any resonant frequency within the audio band was energized it would repeatedly receive input energy, driving resonance and causing physical movement within the cable despite any internal dissipation mechanisms. A cable should then pulsate, which it does not by any detectable amount.

Equal sensation magnitude curves

From the provided curve, threshold sensitivity of touch ranges between 1x10-7 meters to 1.5x10-6 meters in amplitude to vibrations, depending on signal frequency. This means that some very small vibrations should be detectable by touch.

There will be no significant mechanical resonance in the cable components that will affect the audible output and electrical resonance does not occur until well into the LC region. Wires encased in their dielectric will not move by a significant amount from acoustic transmission, internal electromagnetic field action, or any other such phenomenon by a significant amount to be audible within scientifically established limits of human hearing.

An LC line driven with a low-impedance source

Dr. Howard Johnson, High Speed Signal Propagation: Advanced Black Magic

Stability, Directionality and Conclusion

To illustrate how little internal movement occurs, we will look at a 10 AWG wire that at 0.102 in (0.259 cm) diameter is rated to carry a current (I) of 30 amps. With a 0.040 inch PVC insulator and a 0.040 in (0.102 cm) jacket around a twisted pair configuration, the nominal outside diameter (d) of the wire and insulation is 0.182 in (0.462 cm) which also equals the center to center separation of the wire pair. Using these numbers, we can calculate the force of one wire against the second when current flow in opposite directions, which causes repulsion.

Magnetic Field:

= 0.00130 T;

Force per length:

= 0.0390 N/m

The amount of movement that will be produced by these two wires constrained in a jacket can be determined from the equations for a cylindrical pressure vessel. If we assume that there is a sufficient twist pitch that the forces generate an average uniform force outwards in all directions we can calculate the approximate increase in size of the jacket. The inside diameter of the jacket will be 2d = 0.924 cm with a circumference of 2.903 cm, which gives an internal pressure:

The radial expansion can be calculated from the internal pressure (p) on a cylinder of known thickness (b = 0.102 cm), radius (r = 0.513 cm to mid thickness), and elastic modulus (for extruded PVC E = 0.00179 to 4.83 GPa). If we use the lower bound of E = 1790000 Pa, we get the following increase to the radius:

The diameter increases by 38.8 nm, which is an order of magnitude smaller than the lower bound wavelength of ultraviolet light at 280 nm. Not very much movement at all, one might even say insignificant.

To illustrate how little external movement occurs from acoustic

transmission, we will look at a very high pressure change. Using values

from our previous example of internal movement from electromagnetic

forces, we will look at a 30 Pa acoustic pressure change, which is just

over 120 dB, to calculate the amplitude of the air movement using the

speed of sound in air at c = 343.2 m/s and the density of air  at 20oC, air

has a displacement amplitude based on the characteristic impedance of air:

at 20oC, air

has a displacement amplitude based on the characteristic impedance of air:

For a frequency of 20 Hz, the amount of movement of a wire in its

own electric field will produce movement of only 0.58 mm and 20 kHz of

only 0.58 . The velocity of air particles when they displace is:

. The velocity of air particles when they displace is:

The particle velocity is a constant with frequency as this term cancels out. As a simplification, if we assume that the cable moves at the rate of the surrounding air with only a phase lag, the velocity of the 12’-0” wire will produce an emf voltage in the speaker cable:

As an upper bound solution, we have an addition of three thousandths of a dBV to the signal, not very much at all.

Then we have another misused engineering term, stability, which is not the same as stiffness, as implied here by speaking of preventing movement.

Mechanical Stability

The ANJOU Speaker Cable has been meticulously designed to minimize physical movement within the cable.

The ANJOU Speaker cable has been designed to have exceptional strength and stability, requiring large amounts of force to create any movement.

Various, Pear Cable: Anjou Speaker Cable

Stability as a mathematical concept is the sensitivity of a function to small perturbations. A stable system will not undergo disproportionate change in response to the perturbation.

The concept is applied in engineering mechanics to consider how difficult it is to displace material from a state of equilibrium. In solid mechanics, an object is unstable if a slight load increase or movement causes unbounded deformation. Such a system is on the verge of collapse with the loss of load bearing capacity known as buckling or instability.

The levels of acoustic and electromagnetic forces that occur in any speaker cable design are not about to cause the cable to go flopping around the listening room or even cause the individual conductors to go flopping around inside the outer jacket through either a loss of mechanical stability or resonant behavior.

Incidentally, if the cables did actually have any sort of exceptional stiffness to prevent movement, one would be hard pressed to bend the cables around the back of amplifiers and speakers to a make connection. This is just another exaggeration I’m afraid.

Pear then states a need for internal cable damping, which assumes there is a mechanical resonance issue. Resonance only occurs at specific frequencies, known as modes, and each modal harmonic is increasingly less significant. It is well known from vibration theory that if there is a not significant energy input from a frequency near a resonant peak that damping does nothing.

Pear is also worried about cable movement relative to connectors, but any well made termination will eliminate movement and any potential for noise:

The only other thing that is important is that the cables are properly terminated so they don't become noisy, and that the shield is of good quality and provides complete protection from external interfering signals. Terminations will normally be either soldered or crimped, and either is fine as long as it is well made. For the constructor, soldering is usually better, since proper crimping tools are expensive.

The Truth About Interconnects and Cables

Differential length is just not important, as there is certainly more variation in distance between the listener’s ears and each speaker than the fractional inch differences in wire length. When one considers that sound in air travels at 1130 ft/s is many orders or magnitude slower than electricity in a copper wire which approaches the speed of light at 42-72% of c (c = 983,571,056 ft/s), the differences will be exaggerated even further. For a 100 ft difference in cable length at .42c verses a 1 ft difference in ear location:

Calculations provided by Audioholics have previously shown signal loss in 50ft of 12AWG standard zip cord to be less than 1 dB at 20 kHz and group delay of 209 ns = 209x10-9seconds, which is six orders of magnitude smaller than 5x10-3 seconds that a human can hear only under optimal test conditions.

As far as high frequency attenuation, the 1 ft difference in relative ear location does not even get into the off axis high frequency attenuation due to the speakers. Any differences in the angle of each ear relative to each speaker axis, that likely accompanies the difference in ear position, will be far more detrimental than any attenuation from different cable lengths.

Cable directionality is a complete fabrication, especially when considering the cyclic nature of AC:

Your ANJOU interconnects are marked with directional arrows that indicate the direction that the conductors were drawn in. This is primarily a result of general engineering practices to control as many variables as possible. Some people feel that the cables sound better when the cables are aligned with the directional arrows with the “direction” of the signal. It is important to remember that the audio signal is fundamentally AC and thus the electrons are moving both forward and backward. The final word on this subject is that Pear Cable recommends hooking up the cables following the directional arrows. This recommendation is based on the simple principle of controlling as many variables as possible.

Pear FAQ 5: Are ANJOU interconnects directional?

Here is another mechanics error: drawn wire will have no longitudinal variation in properties and is unaffected by which end is held in place and which end is pulled. Relative to the metal that is being drawn, a Free Body Diagram of the forces involved will show an equal an opposite force at both ends consistent with Newton’s Laws of Motion; basic mechanics. Relative to the wire, both ends are pulled equally so there is no variable to control. This problem is an elementary topic that should be readily identifiable and solvable to any second year engineering student.

Finally, another Audioholics favorite, audio cable break in:

You may listen to your cables directly out of the box and get most of the performance immediately. However, it will take approximately 1 day for the cables to mechanically settle after they have been moved or set up for the first time, which can have an effect on the sound. Some users do report a need for our cables to "break in" over time to achieve the optimum performance. Customers must make their own decision as to how long is necessary to "break in" the cables, but do not hesitate to listen to them immediately.

Pear FAQ 8: Do I need to “Break-In” my cables?

The statement that cables mechanically settle is utter BS but let’s entertain two possibilities.

The only place one will see settlement published as a recognized engineering term is as a phenomenon in soil mechanics and foundation engineering. It occurs when a significant change in load is applied to soil, which causes consolidation of the soil where water is squeezed out, decreasing the soil volume. Such an event should not occur in speaker cables.

The other possibility is that if by settlement the phenomenon of creep is implied by this improper terminology, it is also a non-issue for audio. Creep occurs when a material is loaded and the deformation increases over time with no change in load, resulting in microscopic volumetric and density changes. Many polymers do exhibit creep but metals do not exhibit any significant creep. Moving speaker cables is unlikely to cause any significant creep, and even implying that such would be a source for cable break in would mean that any time a cable was relocated it would again require brake in. Audiophiles claim to hear break in only when cables are new, not when they have relocated cables they have owned longer than the supposed initial break in.

In closing, there are numerous stories of believers in magic cables being caught hearing what they want, not what is present to be heard:

John Dunlavy, who manufactures audiophile loudspeakers and wire to go with it, does think questioning is valid. A musician and engineer, Mr. Dunlavy said as an academic exercise he used principles of physics relating to transmission line and network theory to produce a high-end cable. "People ask if they will hear a difference, and I tell them no," he said.

Mr. Dunlavy has often gathered audio critics in his Colorado Springs lab for a demonstration.

"What we do is kind of dirty and stinky," he said. "We say we are starting with a 12 AWG zip cord, and we position a technician behind each speaker to change the cables out." The technicians hold up fancy-looking cables before they disappear behind the speakers. The critics debate the sound characteristics of each wire. "They describe huge changes and they say, 'Oh my God, John, tell me you can hear that difference,'" Mr. Dunlavy said. The trick is the technicians never actually change the cables, he said, adding, "It's the placebo effect."

A Spat Among Audiophiles Over High-End Speaker Wire

Roy Furchgott, The New York Times

From: The Truth About Interconnects and Cables

Mr. Dunlavy has made similar criticisms about the claims of exotic cable manufacturers on other occasions as well. Cable magic is nothing but the placebo effect.

Engineering Judgment

Good engineering judgment is based on the knowledge and experience that distinguishes good engineering from poor. Knowing what constitutes a significant design parameter to consider and what does not is crucial. Poor engineering judgment leads to flawed designs that do not solve the intended problems or are unnecessarily expensive. Diminishing returns, a fundamental principle of modern economics, weighs heavily on any extreme design. A good engineer recognizes this fact and uses engineering judgment to consider the significance of the factors and designs only for the ones that matter in order of relative importance.

For $302 per foot, Pear Cable has not shown proof that they can provide any significant audible improvements that justify the cost. As illustrated in this discussion using established engineering and scientific knowledge, the significance of the design parameters that Pear considers important are easily questioned, leaving the onus of proof on Pear to prove their designs and not the other way around as Pear has suggested.

In addition to the insignificant effect that cable has to the overall system performance, numerous other factors that further trivialize the significance of speaker wire and interconnect on audio performance:

- Limits of the quality of the original recording and recording equipment

- Limits of circuit traces and internal wiring quality in the reproduction electronics

- Other gear you could buy for seven thousand dollars

If in fact, the Anjou cables do cost as much as claimed to engineer and manufacture, there is a significant waste of engineering effort and manufacturing resources to accomplish very little if anything.

The challenge by the JREF was an opportunity for Pear to prove the significance of the design parameters that they deem important and that they believe in their product.

Pear Cable has the utmost confidence in the products that we offer, and the products have all had their scientific principles verified by human listening. We can stand behind all of the design principles that we utilize; can the other guys do that?

Instead, Pear has chosen to avoid having the significance of their scientific principles verified by human hearing under controlled, scientific circumstances in public which only serves to put their integrity further into question.

Conclusion: So What Does $7250 Buy?

Cables are simply electrical wave guides to transmit signal between audio components. While cables do posses electrical properties that interact within a circuit, those properties are generally insignificant to those of other system components when properly designed. A properly designed cable should cause minimal signal loss and have no effect on the balance of frequency content in the signal, which simply means a flat frequency response. Cables that can not do this degrade the sound quality, irrespective of their cost.

As a case study, we have put a single company under the microscope to illustrate how to identify many of the fallacies promulgated by exotic cable manufacturers. All of the issues that have been brought up in this discussion are equally valid for any audio cable manufacturer that makes these claims. An analysis such as this can and should be performed on any product manufacturer that charges an exorbitant or disproportionate amount of money for a simple product that comes with claims of equally disproportionate benefits or improvements.

While dissecting marketing BS posing as scientific proof and engineering design casts a very long shadow over the credibility of a product manufacturer when there is a clear misuse of scientific principles, it is not direct proof that an actual design does not work as claimed; for that, we will turn to experimental testing. Based on the only testing supplied by Pear Cable, the anonymous frequency response plot, we ask the $7250/12 ft pair question:

What does $7250 for speaker cables really buy?

It buys a very expensive filter.

References

-

Everest, F. Alton, Master Handbook of Acoustics, Fourth Edition, McGraw-Hill, 2001

-

Davis, Don, Patronis, E., Jr., Sound System Engineering, Third Edition, Elsevier, 2006

-

Bies, D.A., Hansen, C.H., Engineering Noise Control, Theory and Practice, Third Edition, Spon Press, 2003

-

Timoshenko, S.P., Gere, J.M., Mechanics of Materials, Third Edition, PWS-Kent Publishing Company, 1990

-

Roylance, D., Pressure Vessels, Department of Material Science and Engineering, Massachusetts Institute of Technology

-

Clough, R.W., Penzen, J., Dynamics of Structures, Second Edition, McGraw Hill, 1993

-

Johnson, H., Graham, M., High Speed Signal Propagation: Advanced Black Magic, Prentice Hall, 2003

-

Gunther, E., Skinscape: A Tool for Composition in the Tactile Modality, Masters of Engineering Theses, Massachusetts Institute of Technology, 2001

-

Verrillo, R.T., Fraioli, A.J, and Smith, R.L. Sensation Magnitude of Vibrotactile Stimuli, Perceptual Psychophysics, 6, pp. 366-372, 1969.